- TOP

- KIMOTO Film Products

- Film for Must-Transfer Process KIMOTO MT ™

Carrier Film for Mass Transfer Processes KIMOTO MT™

Mini LED/Micro LED Mass Production|High Performance Pressure Sensitive Adhesive Film for Industrial Use

Film KIMOTO MT™ for mass transfer processes is an adhesive film optimized for the manufacturing process of high-performance electronic components such as Mini LEDs and Micro LEDs. In addition to its excellent smoothness and stable adhesive properties, it also has excellent heat and chemical resistance, and provides stable performance even under harsh process conditions.

It realizes high-precision mass transfer of fine and high-density parts, and supports mass production. It is a process film that meets the needs of high-performance electronic component manufacturers by achieving both the precision and efficiency required for mass production of Mini LEDs and Micro LEDs.

Features of KIMOTO MT™

-

Excellent smoothness

Mini LED/Micro LED, etc.

It is possible to lay products with a side of tens to hundreds of μm flat -

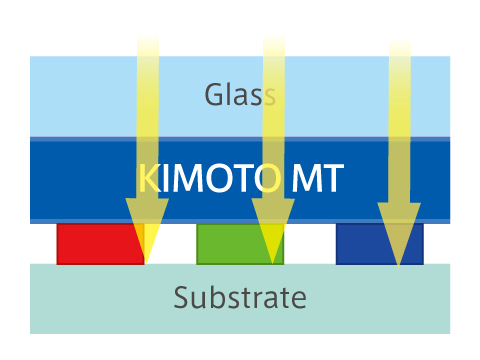

Removable

Double-sided silicone adhesive that does not easily contain air bubbles and is easy to peel off, making it ideal for temporary storage with little glue residue

-

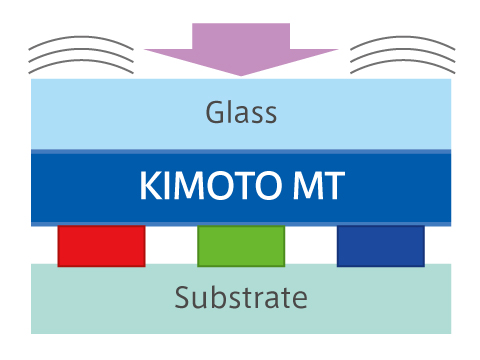

Cushioning

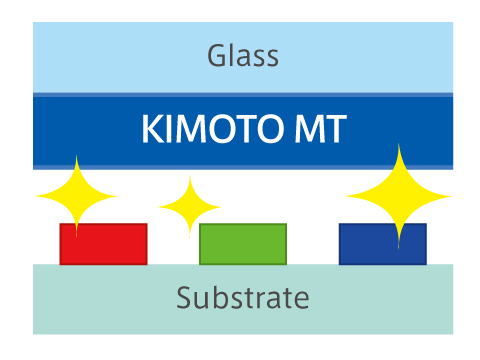

Cushioning that absorbs shock during the mass transfer process and prevents damage to parts

-

High transmittance

Since it uses a highly transparent film, it is easy to align and has excellent workability.

Applications

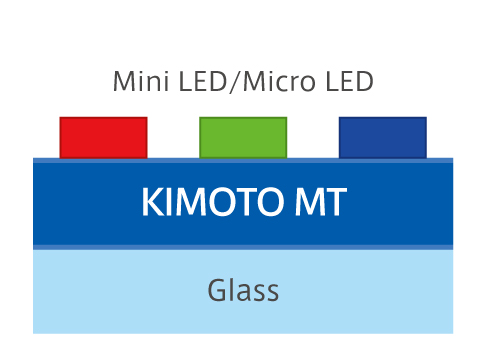

Carrier film in the Mini LED/Micro LED mass transfer process.

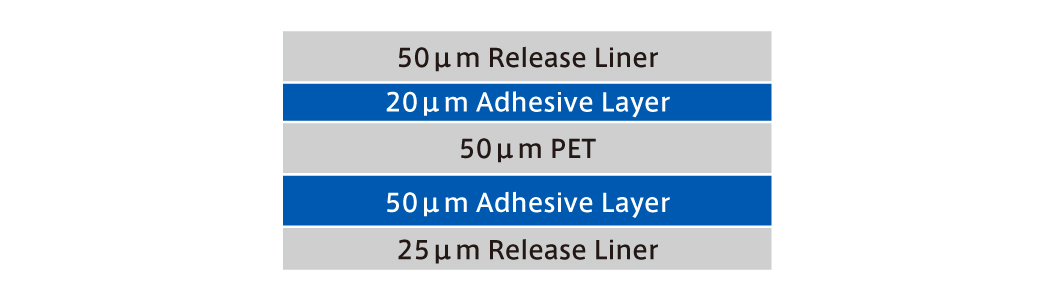

Structure

Lineup

| type | Characteristics | Base material | Separator |

|---|---|---|---|

| KIMOTO MT ™ 003 | Double-sided silicone | 50μm | 25μm/50μm |